Unveiling the Quality of Chinese Furniture Hardware

The Essence of Quality in Chinese Furniture Hardware Manufacturing

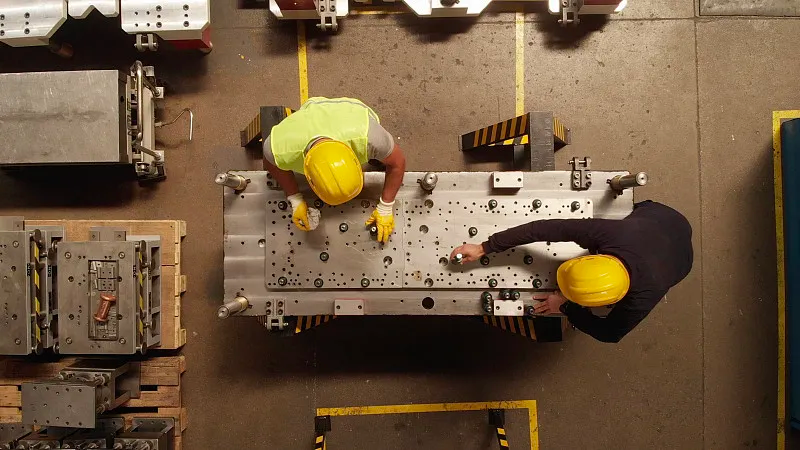

Earning the trust of clients in the furniture hardware industry hinges on a manufacturer’s ability to consistently produce high-quality stamped metal parts. There are numerous factors that influence the quality of these hardware components, and understanding them can simplify the process of selecting the right furniture hardware production factory.

Factor 1: Mold Materials

Mold materials are one of the most critical factors affecting the quality of furniture hardware stampings. Good processing begins with the right tools, and qualified manufacturers pay close attention to mold materials and the requirements of the stamped products.

The material for stamping molds depends on the type and characteristics of the product. Typically, ordinary steel is used for thin-walled and large surface area stampings. However, for producing high-precision, thin-walled complex parts, materials of equal or higher quality than P20 steel are employed.

Factor 2: Precision

The precision of the mold determines the smoothness of the hardware parts and the outcome of the forming process. Greater precision can significantly enhance the quality of hardware stampings.

When selecting a furniture hardware stamping manufacturer, inquire if you can visit the factory for inspection. Check if they have advanced measurement equipment, such as laser measurement tools, to ensure mold precision. If the factory is too far, requesting samples or factory images and videos can be a more cost-effective alternative.

Factor 3: Quantity of Stampings

The number of times a hardware part is stamped significantly affects its tolerance. When choosing a high-quality hardware stamping manufacturer, this issue must be considered.

For thin furniture hardware parts, it’s best to perform a few stampings after the forming process, as it requires fewer secondary operations and avoids leaving marks on the product. However, multiple stampings are a good choice if they enhance the product’s aesthetic appearance.

Factor 4: Surface Roughness

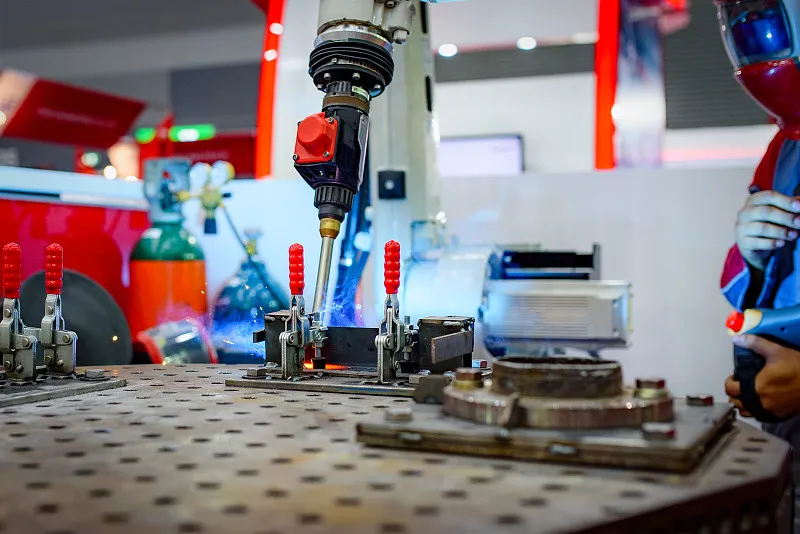

Surface roughness is a key factor in determining whether the product will be smooth and visually appealing after forming.

High-quality hardware parts should have a mirror or satin finish, which can be achieved through surface grinding operations. This increases the smoothness of the hardware surface, facilitating subsequent surface treatment processes and removing burrs and sharp edges from the stampings.

Factor 5: Surface Treatment

Surface treatment for progressive die hardware stampings differs from that of transfer die metal stampings. Surface treatment significantly improves the quality and performance of hardware stampings. It is customized according to different needs, such as using original color, bright chrome, or metal powder spray for stainless steel hardware.

Factor 6: Part Inspection

When choosing a professional Chinese metal stamping manufacturer, check if they have the necessary equipment, such as Coordinate Measuring Machines (CMM) and Ultrasonic Testing (UT), to ensure product quality.

Prefer manufacturers with in-house laboratories that can perform hardness tests on molds and finished products weekly. This helps avoid unexpected issues after stamping manufacturing.

There are two inspection methods in the hardware stamping industry:

- Random review, conducted by machine operators during the manufacturing process.

- One hundred percent final inspection before packaging, which can only be done by high-quality workers.

Delivery Schedules

To meet urgent demands, many furniture hardware factories struggle to deliver a large number of parts on time due to varying production workloads.

When clients order high-quality stampings, it’s crucial to confirm with the hardware factory about their production capacity and the time required to produce the products after placing an order. A factory that is punctual and efficient can be considered a professional and reliable supplier.

Marking and Painting

Marking and painting are key processes for furniture brands to make their final products look their best through brand names, models, and/or other descriptive information.

High-quality metal stampings are equipped with advanced 3D laser marking equipment, providing precise marking and high processing speeds. These are automated machines that reduce labor costs for these procedures. However, they are expensive, and many hardware factories do not have such machines, often collaborating with nearby marking factories to complete this processing.

Quality Control Processes

Quality control is always one of the most critical factors in determining whether a client’s hardware stampings meet their requirements.

High-quality manufacturers should have quality control personnel responsible for testing the product’s qualification at each procedure.

The factory’s testing procedures should be defined according to the client’s quality indicators and national standards. When communicating with the hardware factory, specify your requirements, asking the factory to adhere to American, European, or other types of product quality standards.

Packaging and Transportation

Proper packaging and transportation can reduce the risk of damage to stampings, especially for large and/or heavy parts.

Before production, consult with the hardware manufacturer about their packaging and transportation options. Additionally, if possible, provide samples of similar products and test the packaging and transportation.

Pricing

Pricing is a factor that cannot be overlooked when selecting a hardware stamping manufacturer, but it does not mean that the lowest price is the best choice.

Quality and service levels are also reflected in the price, so do not mistakenly choose based solely on cost. Compare based on price and service levels before making a selection.

Reliability

The best way to determine reliability is through word of mouth from peer companies about quality suppliers, which is unlikely to be disclosed.

After-Sales Service

Pay attention to the after-sales service provided by the furniture hardware manufacturer. If there are issues with the hardware products, the supplier should immediately provide after-sales service according to the client’s requirements, including remanufacturing and repairs.

A professional metal hardware factory should have a machine repair department and spare parts storage to prepare for any unexpected situations during production. Even if it takes longer.

Selecting a high-quality hardware stamping manufacturer is a lengthy and detailed process, requiring the assessment of multiple factors before signing a contract.

Given the many considerations when choosing a high-quality hardware stamping manufacturer, obtaining professional advice before placing an order is crucial.