Embracing Automation in Furniture Hardware Manufacturing: A Path to Durability and Efficiency

Unlocking the Secrets to Long-lasting Furniture with Smart Hardware Manufacturing

In the realm of home furnishings, the hardware may be small, but it carries the essence of the furniture’s longevity and daily usability. As industry strides towards Intelligent and automation, the impact on furniture hardware manufacturing is profound. Let’s delve into how advanced automation is revolutionizing the durability and efficiency of furniture hardware in China.

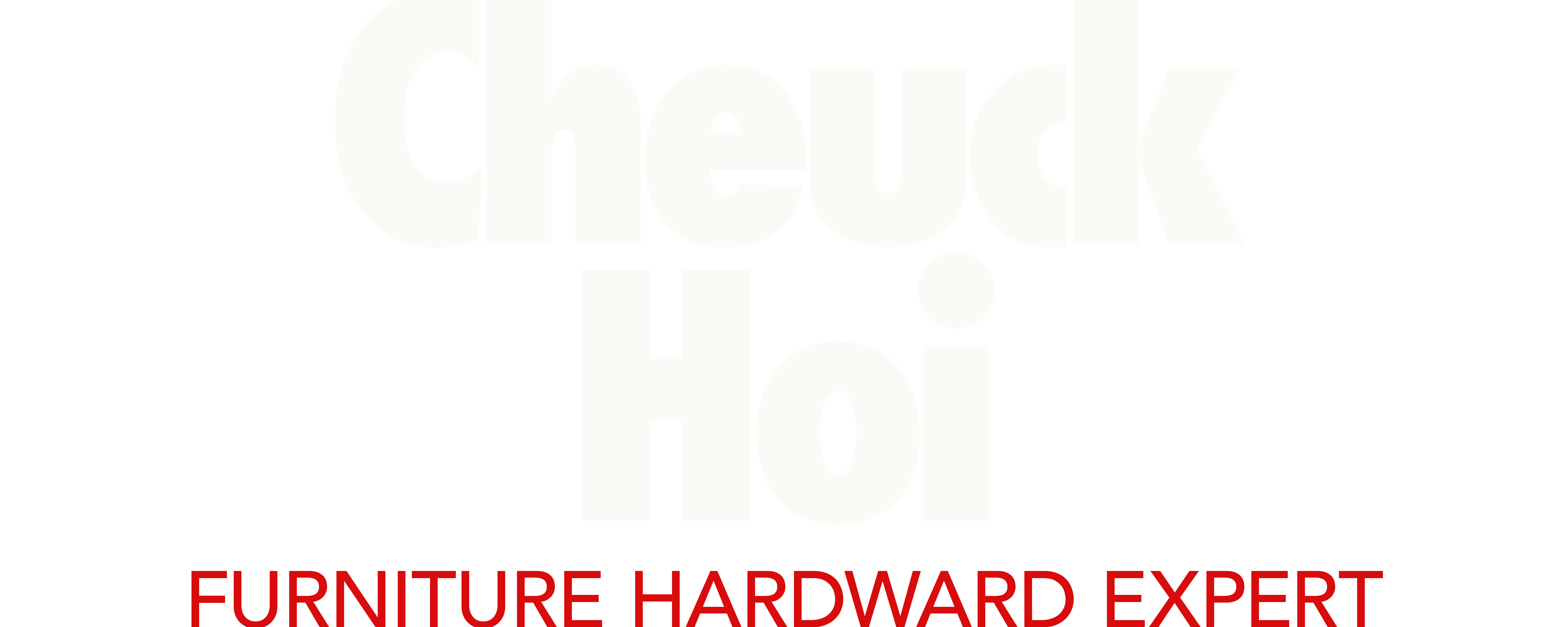

Automated Welding Lines: A Leap in Quality and Efficiency

In the modern industrial landscape, the relentless innovation in welding technology is pivotal for enhancing product quality, increasing production efficiency, and reducing costs. Our sofa leg hardware products utilize laser automatic welding machines as a cutting-edge solution. With their exceptional performance and significant advantages, they’re becoming the preferred choice for many international furniture enterprises looking to source high-quality hardware.

As the trend of intelligent manufacturing continues to grow, more furniture hardware manufacturers are adopting automated welding processes. These automated welding lines not only achieve intelligent planning in the factory but also feature a core automated ‘brain’ that analyzes and processes issues in real-time. The benefits of such lines include real-time data collection, quality inspection through various sensors, and flexible production that enhances product quality, making operations easy and quick for workers to master.

Advantages of Automated Welding Lines:

- Real-time Data Collection: During the production of sofa legs and assembly, automated welding lines can automatically collect data through sensors. Electronic dashboards display real-time production statuses, and any welding issues trigger immediate alarm signals, facilitating quick detection and resolution of problems.

- Flexible Adjustments for Diverse Functions: Automated welding lines support the mixed-line production and assembly of various similar products. They can easily adjust processes to accommodate small batches and a variety of products. When changing workpieces, simple repetitive programming is all it takes to get welding tasks done with ease.

- Easy Operation for Workers: Automated welding lines achieve fully intelligent production, allowing one person to operate an entire line. During quality control, operators follow on-screen prompts, making intelligent operations manageable and significantly boosting production efficiency.

Performance Features of Sofa Leg Automated Welding Machines

- High-Precision Welding Positioning: Our laser automatic welding machines for sofa leg hardware use advanced optical systems and precise motion control technology. They achieve welding positioning accuracy at the millimeter or even micrometer level. This ensures excellent performance in welding small and delicate parts, guaranteeing the accuracy and consistency of welds, greatly enhancing product quality and reliability.

- Powerful Laser Power Output: Equipped with high-power laser sources, these machines can output stable and powerful laser beams. They quickly melt and join metal materials and achieve deep weld penetration, meeting the welding needs for materials of various thicknesses. Whether it’s thin or thick plates, laser automatic welding machines handle it with ease.

- High-Speed Welding: Thanks to efficient laser energy transmission and rapid motion control systems, these devices can achieve extremely fast welding speeds. Compared to traditional welding methods, their welding speed can be several or even dozens of times faster, significantly reducing production cycles and bringing substantial efficiency gains to businesses.

- Excellent Weld Quality: Welds produced by laser welding are uniform, dense, and free from pores and slag. The mechanical properties of the welds are good, with high strength and toughness, capable of withstanding significant loads and impacts. Moreover, the weld surface is smooth and flat, requiring no subsequent grinding or processing, saving on machining steps and costs.

- Multi-axis Linkage Welding Capability: Laser automatic welding machines typically have multi-axis linkage functions, enabling complex shapes and multi-angle welding. Whether it’s flat, curved, or three-dimensional structures, the equipment can precisely follow preset trajectories for welding, meeting the demands of various complex workpieces.

- Intelligent Control System: The devices are equipped with advanced intelligent control systems featuring parameter setting, real-time monitoring, fault diagnosis, and automatic alarms. Operators can easily set welding parameters via touch screens or computer software, and the system automatically controls the process according to the set parameters, ensuring the stability and consistency of the welding process. The system also monitors various data during welding, such as laser power, welding speed, and temperature, and issues timely alerts in case of abnormalities.

- Good Compatibility and Scalability: Laser automatic welding machines boast excellent compatibility, seamlessly integrating with other equipment like automated production lines and robots to achieve a fully automated production process. Additionally, the equipment is scalable, allowing for upgrades and modifications based on the development needs and production scale of the enterprise, meeting the evolving market demands.

Product Advantages

- Enhanced Production Efficiency: The high-speed welding and automated processes significantly reduce welding time, increasing output per unit of time. The elimination of subsequent grinding and processing steps further saves time and labor costs, thereby markedly improving production efficiency.

- Improved Product Quality: High-precision welding positioning, excellent weld quality, and stable welding process control ensure that the welding quality of products meets high standards. This helps enhance the reliability and service life of products, strengthening the competitiveness of the enterprise in the market.

- Reduced Production Costs: Although the initial investment in platform laser automatic welding machines is relatively high, in the long run, it can effectively reduce production costs by improving production efficiency, reducing material waste, lowering labor costs, and decreasing the scrap rate. Moreover, the low maintenance costs and long service life of the equipment further reduce the operating costs for the enterprise.

- Enhanced Operational Safety: The heat generated during the laser welding process is concentrated, causing less harm to operators. Additionally, the equipment is equipped with comprehensive safety protection devices and intelligent control systems, effectively preventing safety accidents due to operator errors and ensuring the safety of the production process.

- Adaptable to Diverse Production Needs: The multi-axis linkage welding capability, good compatibility, and scalability make platform laser automatic welding machines suitable for the welding needs of different types, shapes, and sizes of workpieces. Whether it’s small-batch, multi-variety sofa leg production or large-scale, standardized sofa leg production, the equipment can flexibly meet the demands, providing the enterprise with more choices and possibilities.

- Promoting Industry Upgrade: Our sofa legs,Using advanced laser automatic welding technology, help factories improve production technology levels and achieve the transformation and upgrading from traditional manufacturing to intelligent manufacturing. This not only enhances the core competitiveness of the enterprise but also promotes the technological progress and development of the entire furniture hardware industry.

As the Chinese furniture hardware manufacturing industry advances alongside industrial progress, the increasing automation has led to higher quality and longer-lasting furniture. The adoption of technologies like precision spot welding machines and automated welding lines has garnered unanimous praise from numerous customers. Let’s continue this journey of innovation, speaking with details, and winning the future with quality in the home furnishing revolution.