What Determines Hardware Prices? 6 Factors Boost Your Savings

In the realm of home decoration, hardware accessories are indispensable, from door hinges and locks to cabinet hinges and pull-out baskets, and even to furniture legs, metal frames, and adjusters. These elements directly impact the quality and aesthetics of home hardware and furniture.

Hardware Categories and Their Scope

The variety of hardware is vast, covering numerous fields. However, hardware factories rarely cross categories in production. For instance, those producing automotive hardware seldom venture into furniture hardware, leading to a diverse classification of hardware accessories.

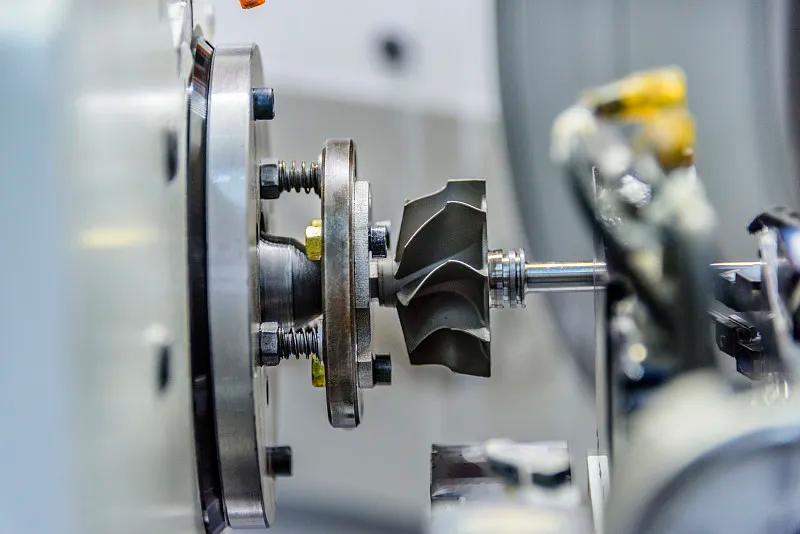

Mechanical Hardware

Mechanical hardware plays a crucial role in industrial production. Fasteners, as key components connecting parts, come in many types, including bolts, nuts, and screws. Statistics show that a medium-sized mechanical manufacturing enterprise can use hundreds of thousands of fasteners annually. Rolling bearings reduce friction and support rotating shafts, widely used in various machinery

Additionally, belts and chains transmit power, while lubricating components ensure the normal operation of machinery. Welding and lifting equipment are also indispensable in mechanical manufacturing and installation.

Architectural Hardware

Architectural hardware covers all aspects of construction. Building profiles and structural components provide a solid framework for buildings, such as aluminum alloy profiles and steel structures. Door and window hardware, including locks, hinges, and handles, ensures the security and enhances the aesthetics of buildings.

Nails and mesh are used for fixing and protection in construction, while plumbing equipment ensures the building’s water supply and drainage systems operate correctly. Firefighting equipment and automatic fire alarms provide vital safety for buildings.

Electrical Hardware

Electrical hardware plays a significant role in power systems. Universal wires and cables are the main carriers of power transmission, and their quality directly relates to the safe and stable operation of power systems. Buttons and switches control the circuit’s continuity, while relays, contactors, and electromagnetic starters play a key role in automated control.

Fuses, circuit breakers, and leakage protectors cut off power promptly in case of circuit faults, protecting equipment and personnel. Control transformers, signal lights, AC motors, and electrical instruments are also essential components of electrical systems.

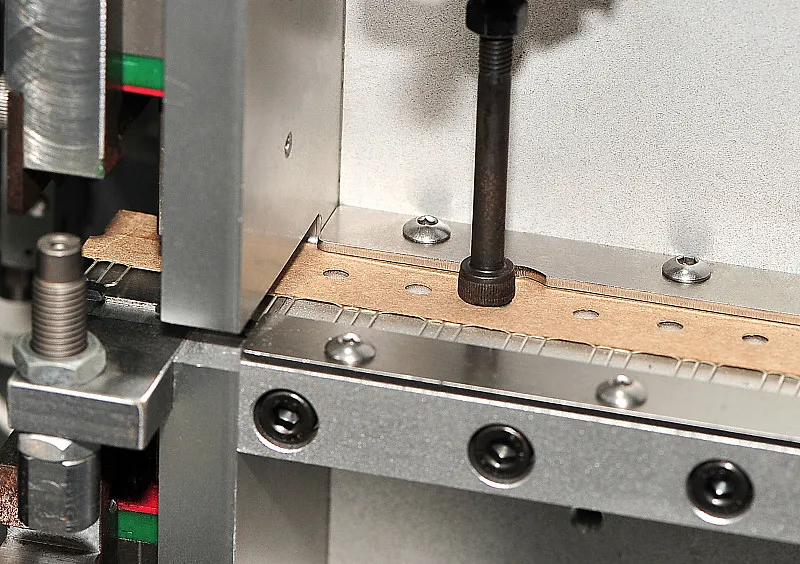

Hardware Tools

Hardware tools are diverse, meeting the needs of various fields. Hand tools like hammers, screwdrivers, and wrenches are commonly used in daily life and small repairs. Power tools, such as drills and saws, are efficient and convenient, widely used in construction and decoration. Pneumatic tools use compressed air as a power source, offering strong power and ease of operation.

Additionally, gardening tools are used for landscape maintenance, cutting tools for metalworking, and measuring tools ensure engineering accuracy.

Furniture Hardware

In the modern home furniture industry, ‘hardware’ still generally refers to a series of metal products, including some new composite materials. These products play a vital role in the manufacturing and assembly of furniture.

Furniture hardware is divided into three main categories: functional, decorative, and basic hardware, with the latter two being the most mentioned in custom furniture.

Factors Affecting Hardware Prices

Design Complexity

Hardware with complex designs often requires advanced processing techniques and more steps. For instance, parts with special shapes, high-precision holes, complex curves, or non-standard threads are more difficult to process.It is estimated that complex-designed hardware can have process costs 30% to 50% higher than ordinary designs due to the need for higher technical level and more precise equipment.

Material Selection

Different hardware materials have significant price differences. Common materials like stainless steel, aluminum alloy, and titanium alloy vary in cost.

For example, stainless steel hinges for doors and windows cost about 1-2 yuan, while aluminum alloy or higher-quality materials can cost up to 3 yuan. High-performance, special materials are not only expensive but also more difficult to process, such as titanium alloy, which is several times more expensive than ordinary steel and requires special equipment and technology, increasing overall processing costs.

Processing Precision

The requirement for precision directly affects the price. High-precision hardware needs more accurate machine tools and measuring equipment, as well as experienced technicians for operation and monitoring.

For parts with tolerances in the micron range, high-precision measuring instruments may be required to ensure dimensional accuracy. This high-precision processing usually requires longer processing times and higher technical levels, leading to increased costs. It is estimated that the cost of high-precision processed hardware can be 20% to 40% higher than ordinary precision.

Batch Size

Batch size is an important factor. Large-scale production can reduce the processing cost per part through economies of scale. In mass production, the preparation costs of jigs and fixtures can be spread over more parts, and production efficiency can be improved.

Conversely, small-batch production, unable to fully realize economies of scale, usually has higher per-part processing costs. Generally, as the batch size of hardware production increases, the unit cost may decrease by 10% to 30%.

Processing Technology

The complexity of processing technology also affects the price. Special processes such as electro-discharge machining, wire cutting, and laser processing often require higher equipment investment and technical requirements compared to traditional turning and milling, thus increasing the processing price. The cost of hardware processed with special processes can be several times that of traditional processes.

For example, the price of precision parts processed with laser processing may be 50% or more higher than those processed with ordinary turning. The surface treatment process and materials used also directly affect the product price.

Market Competition and Regional Differences

Market competition and regional differences also affect hardware accessory prices. In competitive areas, suppliers may lower prices to attract customers; in areas where technical resources are relatively scarce, prices may be higher. Factors such as labor costs, raw material prices, and market demand in different regions can cause price fluctuations.