How to Quote Metal Stamping Hardware for Furniture?

Are you familiar with how to quote for metal stamping hardware parts? In the world of furniture, hardware accessories are like the indispensable soul; they may be small but they support the stability and functionality of the entire piece of furniture. When selecting furniture hardware accessories, everyone hopes to obtain high-quality, precise, and reasonable pricing.

Whether you are an experienced buyer or a newcomer to this field, we are here to provide you with the most practical knowledge and advice. Let’s work together to create higher-quality furniture hardware accessories and contribute to the success of your furniture business. As a loyal partner to furniture merchants, we are committed to providing comprehensive and professional hardware accessory procurement services, giving you an edge in the fierce market competition.

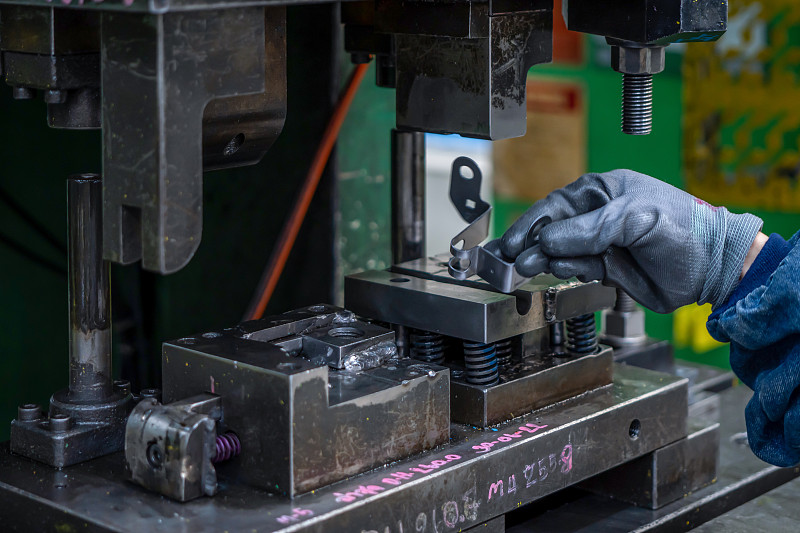

Furniture Hardware Manufacturing Processes

The price of furniture hardware accessories depends on the manufacturing processes involved. Different processes, along with order-specific requirements such as quantity and material, determine the price of furniture hardware parts.

- Stamping Stamping is one of the common processes for manufacturing structural furniture hardware parts. Metal sheets are pressed into the required shapes using molds, followed by bending, welding, and other processes to form the hardware parts. Stamping is suitable for mass production with lower costs but requires the creation of molds, making it suitable for furniture hardware parts with a longer production cycle.

- Casting Casting is an important process for manufacturing large and complex structural furniture hardware parts. Metals are melted and poured into molds, then removed after cooling and solidifying. Casting can produce hardware parts of various shapes and sizes, suitable for furniture structural components that need to withstand significant forces.

- Welding Welding is a process that connects metal pieces together by melting welding rods or wires. Welding is suitable for manufacturing complex structural furniture hardware parts, such as bed frames and cabinet racks. Welding can achieve connections with various metals but requires consideration of welding strength and aesthetics.

- Surface Treatment Surface treatment of furniture hardware parts is an important step in enhancing their appearance and corrosion resistance. Common surface treatments include spraying, electroplating, and anodizing. Different surface treatments can give hardware parts different colors, lusters, and corrosion resistance, increasing the aesthetics and lifespan of furniture.

How to Quote for Metal Stamping Hardware Parts?

Actually, quoting for metal stamping hardware parts is quite straightforward. The quote includes costs such as metal material fees, stamping mold fees, fixture fees, stamping fees, machining fees, and surface treatment fees. Understanding these costs will allow you to provide a quote. Let’s go into detail on how to calculate each cost.

Metal material costs for stamping hardware parts: Open the flat drawing of the stamping part and calculate the unfolded length of the workpiece; then use the calculation formula length × width × thickness × density × unit price (USD/Kg) × (1.1-1.2)/10 (waste) to calculate the material cost.

Calculation method for stamping mold costs: Estimate the punch and die area of the mold based on the shape of the part, add a 5cm allowance on each side, and 3-5cm in height, then refer to the standard of the mold frame according to the mold size.

Stamping costs: Calculated by tonnage. (0.8-1) USD/60 tons, 1.2 USD/80 tons. The fixture and machining costs used in metal stamping hardware parts are not significant and will not be included in this calculation.

Surface treatment costs: Anodizing 0.6 USD/dm (slight variations in quotes among manufacturers); painting; screen printing; spraying; surface galvanizing. Gross profit: Controlled between 20-30%.

Stamping processing fee quoting: Confirm the blank price. The first set of material width, pitch, and thickness will yield the blank weight. Based on the market price of materials, determine the product’s material price.

Confirm the stamping fee: A product is made up of multiple processes, each of which may use a different tonnage press. Each hardware manufacturer will have their corresponding quote.